Veteran-owned by a US Navy Submarines Nuclear Engineer.

Celebrating 27 years!

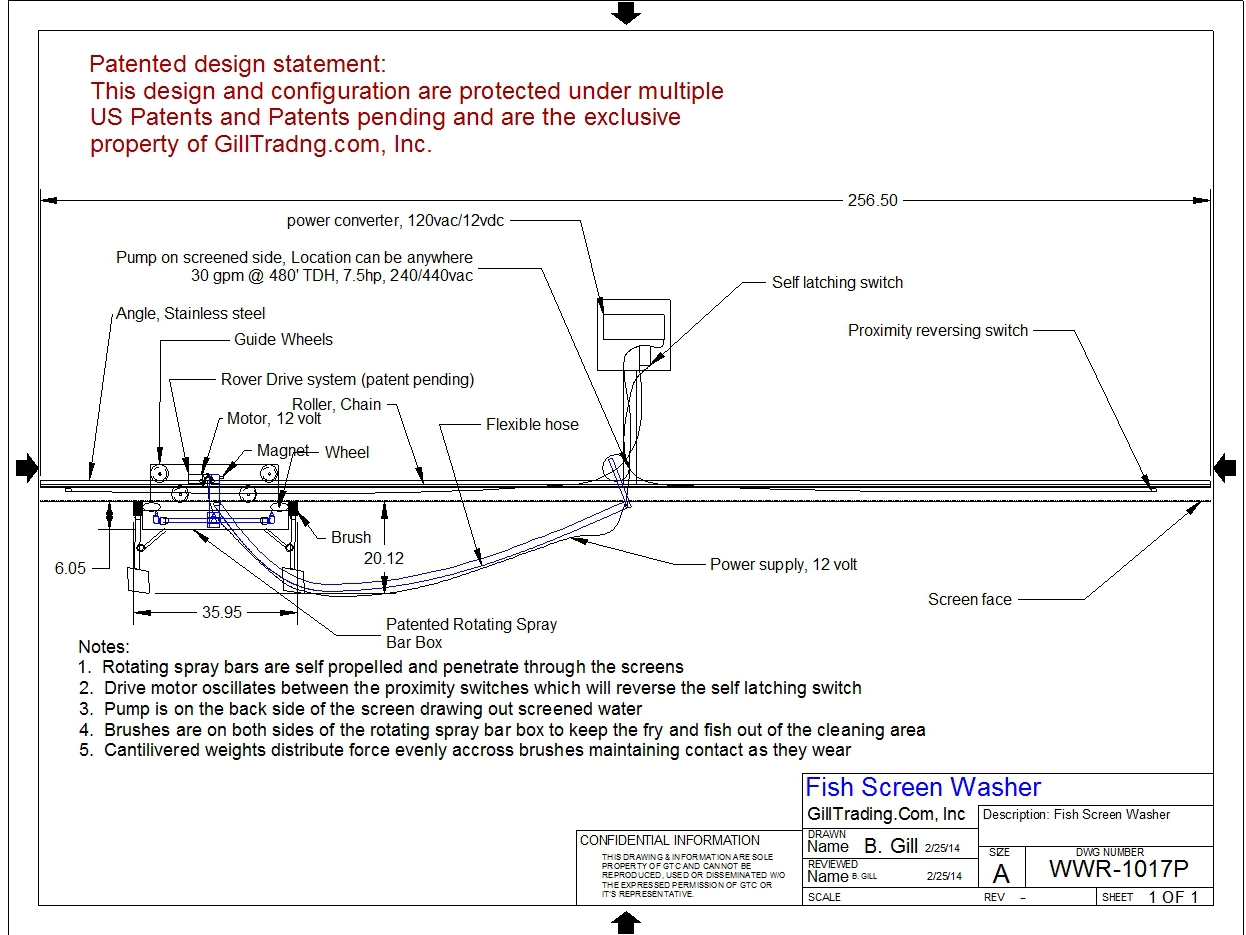

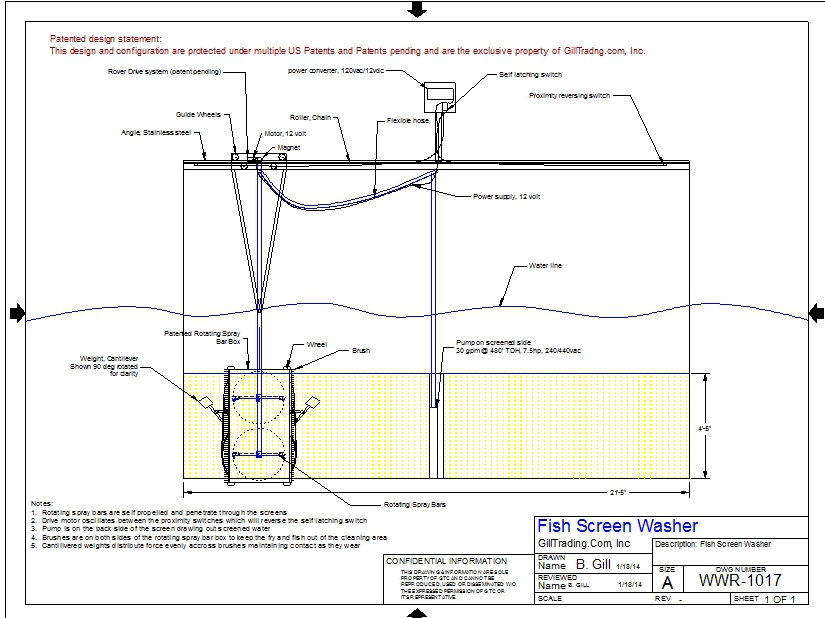

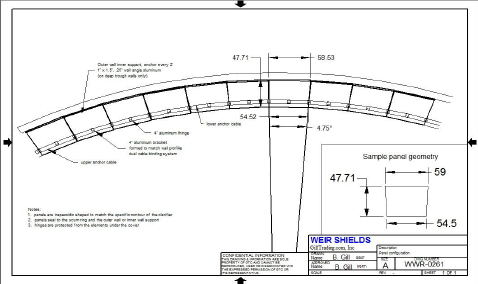

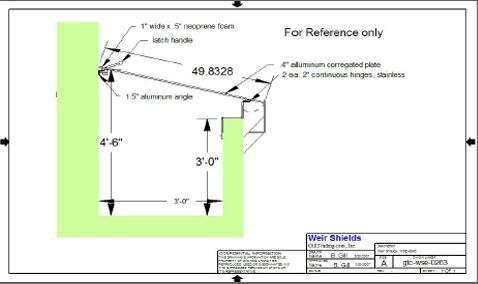

Automated Cleaning Systems remove the algae, scum, grease and other material from the weirs and other surfaces on clarifiers, thickeners, and other tanks. WeirWasher ACS uses the plant’s non-potable water to clean irregular and porous surfaces, bolts, and any other irregularities. We have systems for square and irregular applications as well. WeirWasher ACS designs have been in service for over 27 years. Our nozzles are in use in many industrial applications and have proven to be the best. WeirWasher ACS can clean surfaces under the water level up to one foot under water.

The WeirWasher ACS significantly reduces time in, or near, the treatment equipment while performing cleaning maintenance. It does so by reducing algae fouling in sand filters, UV disinfection, and chlorine contact tanks. As a result, the risk of employees becoming caught on tank components is duly limited, as is their exposure to dangerous bacteria, viruses, and parasites.

The spray penetrates 10 – 14 inches below water line to clean inaccessible/dangerous clarifier designs. It is controlled directly by SCADA, or automatic valve, so manual engagement or disengagement with a hook is not required. The WeirWasher ACS also employs a clarifier bottom cleaning attachment that pre-cleans the tank before anyone enters it.

The WeirWasher ACS offers maximum design flexibility and is suitable for all shapes of clarifiers. It is lightweight (no counter weight required) and has few moving parts. The WeirWasher articulates around obstructions such as walkway supports, dual troughs, and multi-sided launders. It requires NO costly tank changes such as bolt head removal, baffle bracket replacement, or walkway support removal. The system drains when off, so freezing is not an issue

The WeirWasher ACS minimizes costs associated with labor and liability by providing consistent and effective daily cleaning which prohibits large algal bloom growth. This result limits workers’ time in and near the the equipment, as well as exposure to the pathogens within.

The spray penetrates 10 – 14 inches below water line to clean inaccessible/dangerous clarifier designs. It is controlled directly by SCADA, or automatic valve, so manual engagement or disengagement with a hook is not required. The WeirWasher ACS also employs a clarifier bottom cleaning attachment that pre-cleans the tank before anyone enters it.

The WeirWasher ACS optimizes clarifier/thickener performance by allowing consistent flow through weirs which prevents short circuiting and solids collection in the influent trough.

Total Suspended Solids (TSS) are lowered by consistent daily cleaning, including irregular and porous surfaces, and water spray that penetrates 10 – 14 inches below the water surface. The water spray cleans past brackets, walls, etc. to provide effective and consistent algae control. The reduction in TSS minimizes UV chamber fouling, thereby improving UV effectiveness and preventing bulb breakage.

WATER is an EFFECTIVE CLEANER even at lower pressures. There is no need for brushes or scrapers. The narrow cleaning stream and rotation maximize the available pressure for effective material removal. Much less water is used when compared to fire hose method and the WeirWasher uses available non-potable plant water. This system eliminates the need for chemicals used in algae control.

The Weirwasher ACS is a truly dynamic system. It can change with facility capacity. The addition of a booster pump will maximize results as flows increase and sludge and debris are sent back into the solution. A feed well sprayer is also available for foam and sludge accumulation control.