Veteran-owned by a US Navy Submarines Nuclear Engineer.

Celebrating 27 years!

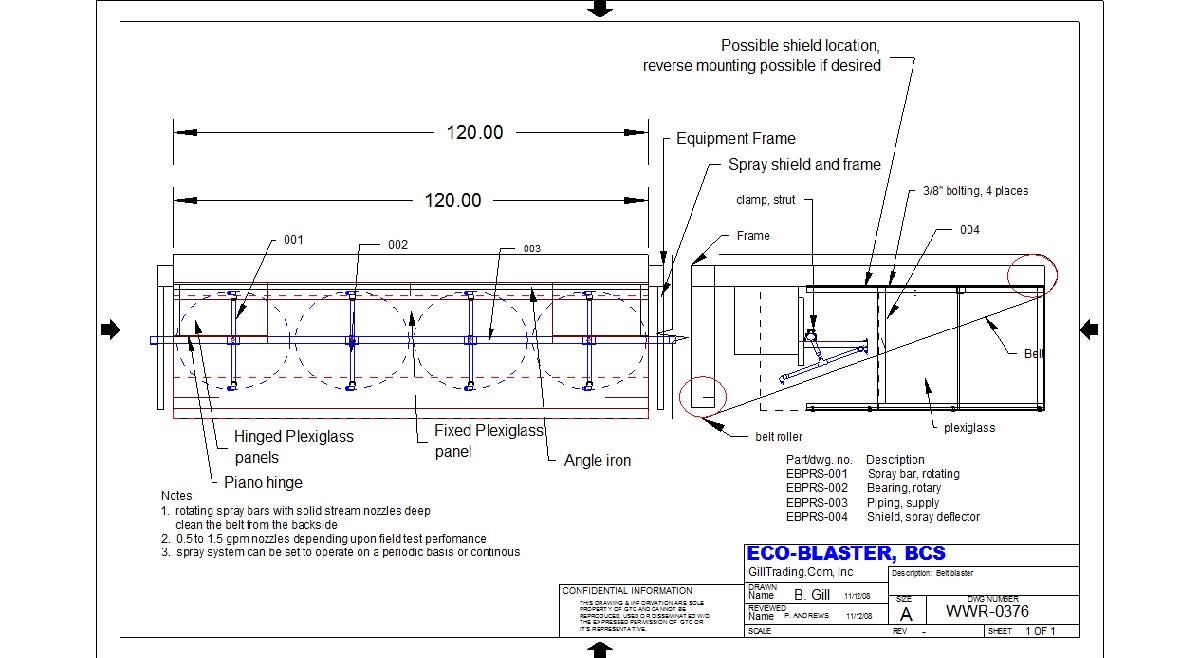

Eco-Blaster, Biological Control Systems (BCS) are designed to address foreign material collection where a linear spray has unsuccessfully been applied. The approach is simply applying a moving spray that prevents collection and re-incorporates the material back into solution and/or removes the offending material. Eco-Blaster, BCS are designed using advanced materials, such as carbon fiber tubing, optimizing the overall durability and longevity.

Eco-Blaster, BCS is a self propelled rotating foreign material control system. Our patented spray systems perform work in inaccessible locations without the need for additional motors or equipment. By gimballing the nozzles we control the thrust vector, which regulates the rotational speed of the Eco-Blaster, BCS. Speed is regulated to optimize the impingement force of each spray apparatus, therefore, maximizing the amount of spray energy delivered to each surface. As the foreign material is suppressed under the Eco-Blaster, BCS, the surface tension is reduced which allows the surrounding material to automatically flow into the Eco-Blaster, BCS suppression zone. This is possible since Eco_Blaster, BCS imparts random inertia into the foreign material which allows the surrounding material to flow under the Eco-Blaster, BCS inherently.

Eco-Blaster, BCS can be rigidly mounted to existing structures or attached to a buoyant platform. The buoyant platform allows for the Eco-Blaster, BCS to rise and lower with the liquid surface thereby allowing for suppression through all process phases.

Eco-Blaster, BCS designs allow for limitless versatility in its application and usage. The Eco-Blaster, BCS can supplement the following equipment:

All Eco-Blaster, BCS systems are precisely engineered and designed for each application. Any location, whether accessible or not, that accumulates debris can be automatically broken up, re-incorporated into solution, cleaned and/or prevented from settling. Combined sewer overflow basins of large size can also be automatically cleaned. Below are some exampled applications:

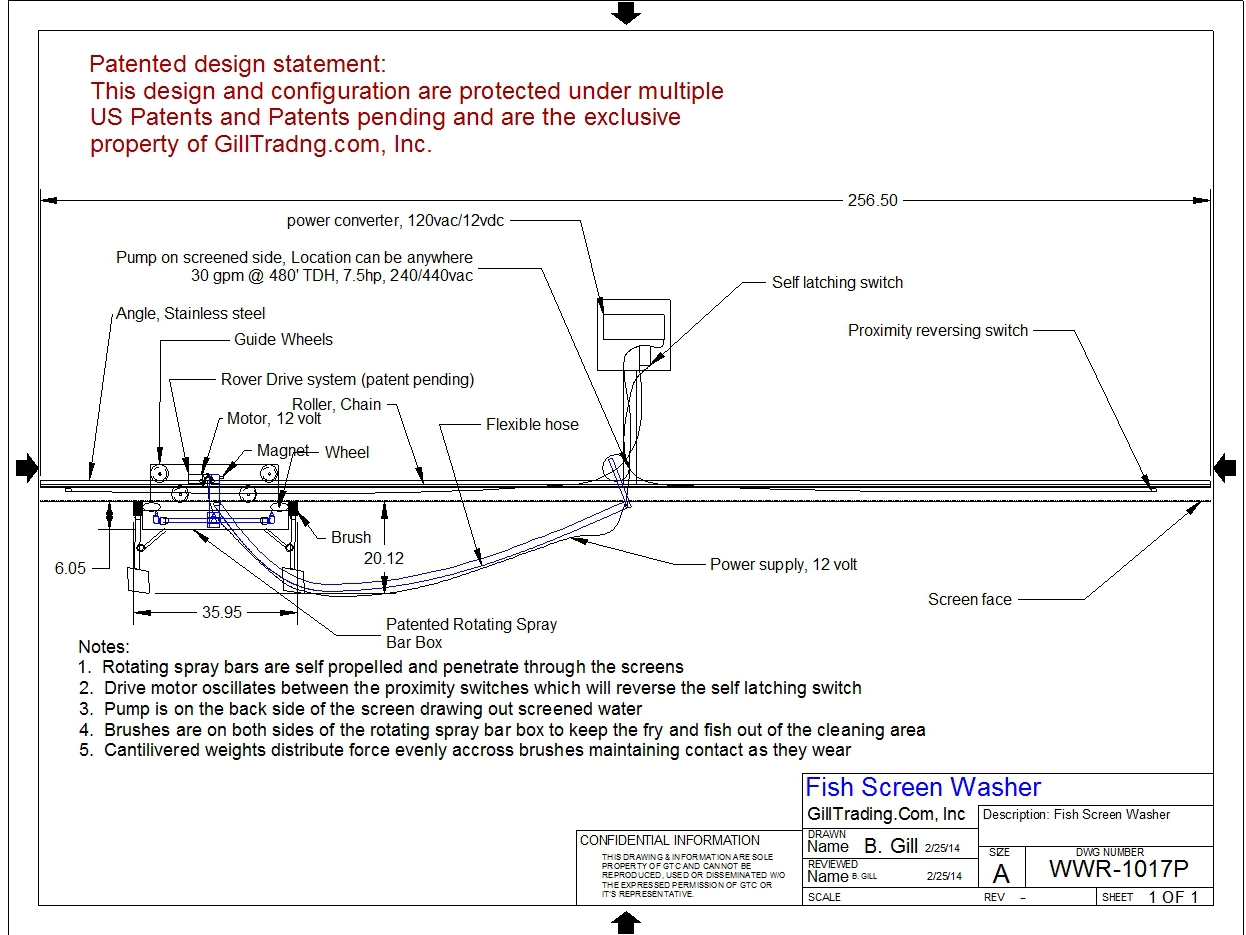

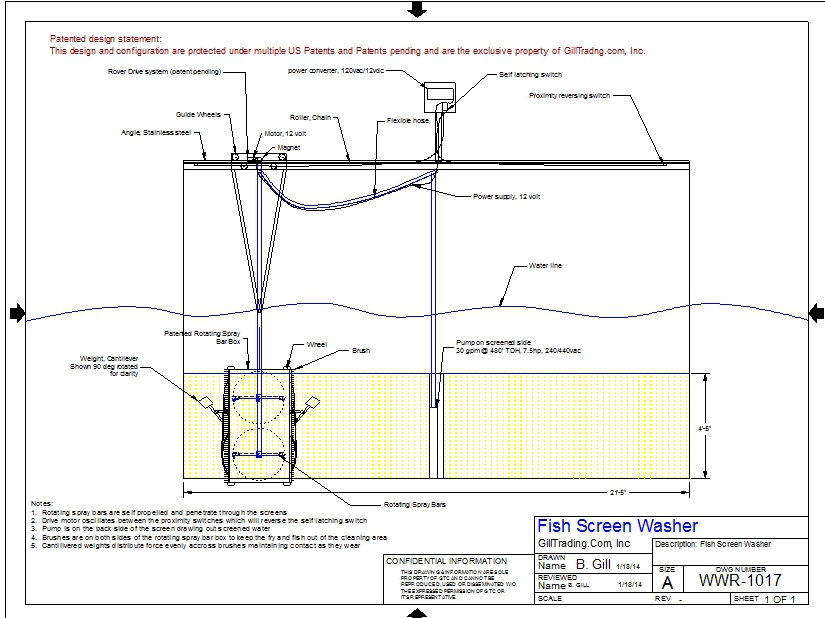

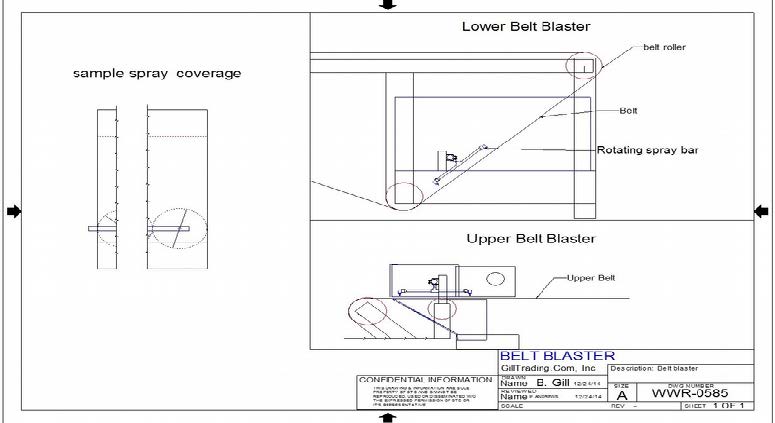

Screen cleaning is one of the most difficult applications for operators to clean and prevent material buildup. The Eco-Blaster, BCS is an economical and very effective cleaner in these challenging locations. Solid stream nozzles allow for an extremely high impingement force on the screen surface, keeping the screen passages free and clear with only periodic use depending upon each application. Belt press fabrics are cleaned better and more efficiently using rotating solid stream nozzles.

Headworks, splitter boxes, and any other surface where materials accumulate can be maintained free of debris build up with the Eco-Blaster, BCS. Heavy accumulations of material will be driven back into solution and then with periodic operation the area is maintained automatically. As the top layer of material is broken up by the cutting power of solid stream nozzles, the lower material rises and is driven into solution or prevented from settling.

Sequential Batch Reactors have various locations that accumulate foreign materials. Foam and scum tend to collect in the pre-aeration zones while algae growth can become a problem in the EQ basin. The Eco-Blaster, BCS versatile mounting configurations address these concerns. A buoyant mounting system will allow the Eco-Blaster, BCS to rise and lower with the liquid level to maintain control.

Clarifiers accumulate foreign material in various areas. Material can become trapped in the center feed well causing odor issues. Eco-Blaster, BCS drives the accumulated material back into solution with periodic operation. Full surface suppression is necessary in many applications due to system upsets throughout the process stream. Each Eco-Blaster, BCS can operate independently and can be used when necessary. Multiple combinations of spray configurations are used to address numerous types of accumulated material.