Veteran-owned by a US Navy Submarines Nuclear Engineer.

Celebrating 27 years!

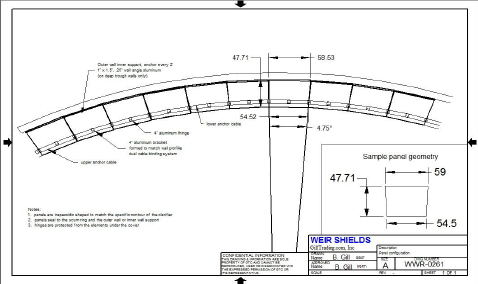

Stainless Weirs are used on tanks and channels to evenly distribute liquid and regulate flow in process industries. Through the use of Stainless Weirs, floating materials are separated from the liquid, and a regulated, even flow will enter the outlet trough then distribute evenly around the tank.

Precisely cut weirs to any desired shape with a flow notching system that from a distance shows the actual flow in the tank relative to the height of the water nappe (tank water level) printed/cut into the side of the weir plate. Field verification of approximate flow at each tank can be known simply by looking at the associated weir notch. Multi-tank flow balancing can be achieved by the use of the weir notches to ensure equal flow is being split between each tank in the field from multi-tank feed distribution boxes.

Patent-pending High Flow Split Plates which are evenly distributed around the circumference of the weirs at each weir plate split create a more even and regulated flow at emergency/beyond design flows improving distribution and settling, resisting short-circuiting or bypassing of the settling of the clarifier.

Stainless Weirs patent-pending design creates lifetime weirs use and can be removed and used again on the next tank.

Measure/balance flow from the field

CNC cut weirs to any desired shape, or custom cut to existing mounting, with a flow notching system (patent pending) that at the tanks shows actual flow in the tank relative to the height of the water nappe (tank water level) with actual flow rates printed/cut into the side of the weir plate. Multi-tank flow balancing can be achieved in the

field when using multi-tank feed distribution boxes, optimizing facility

operations and sludge loading and tank performance.

One bolt per feet for weirs, brackets and waffles welded assembly equals two thirds less bolts

Up to two thirds less installation time due to unitized fabrication! Installation costs greatly reduced due to one bolt per 2 feet mounting for brackets, weirs and baffle compared to the old style 5-6 bolts resulting in less anchors and substantially less time during installation. Weir, baffles & brackets jig welded as one piece to

the exact diameter of each tank.

Weir plate splits create a more even and regulated flow at emergency/beyond design flows improving distribution and settling, resisting short circuiting or bypassing of the settling of the clarifier during extreme flow events.

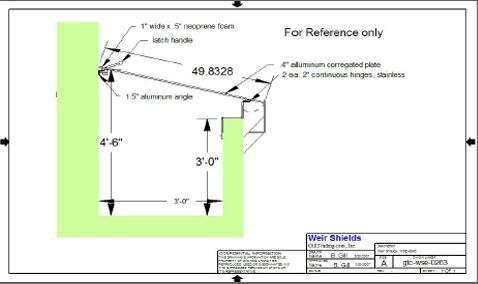

25% increased flow area, 25% reduced flow velocity and less growth area

Precise water jet cut (adjustable if needed) vertical bracket mounting system for the scum baffle that increases total flow area by up to 25% thereby reducing flow velocity allowing for elevated flock blanket, reducing short circuiting/bypass flow/pinflock carryover. The vertical brackets additionally remove the algae growing horizontal surface as well as eliminates the horizontal settling surface for flock, grease and other settling materials. Algae control in the up flow area between the baffle and weirs is much improved due to a low shielded area under the Verti-brackets in comparison to horizontal brackets which block cleaning of the up flow area and submerged inner wall.

Field flow calculation

Notches cut into the weir place create a visual flow gauge at the tank to determine approximate flow at each tank and to field balance flow in multi-tank systems.

Design for improved scum removal of existing scum collection system and is retrofittable to existing deficient systems of older clarifiers and thickeners. Upgrade from the old 1.5 cubic feet per scum beach capture area to 10 cubic feet per scum beach capture. That’s over 6 times the scum removal per scum beach per revolution.