Veteran-owned by a US Navy Submarines Nuclear Engineer.

Celebrating 31 years!

Automated cleaning of transverse and longitudinal applications was impossible, UNTIL NOW! Operators have been required to un-safely enter tanks to clean and remove the accumulation of material in the center of the tanks, outfalls, or other areas. Most situations are dangerous and present possible drowning situations, slip and fall injuries, exposure to untreated materials, and exposure to extremely dangerous environments. With the reduction of facility budgets and staffing, the operational performance of equipment and its maintenance have a tendency to be reduced or neglected. With automated cleaning, plant efficiency can be maintained.

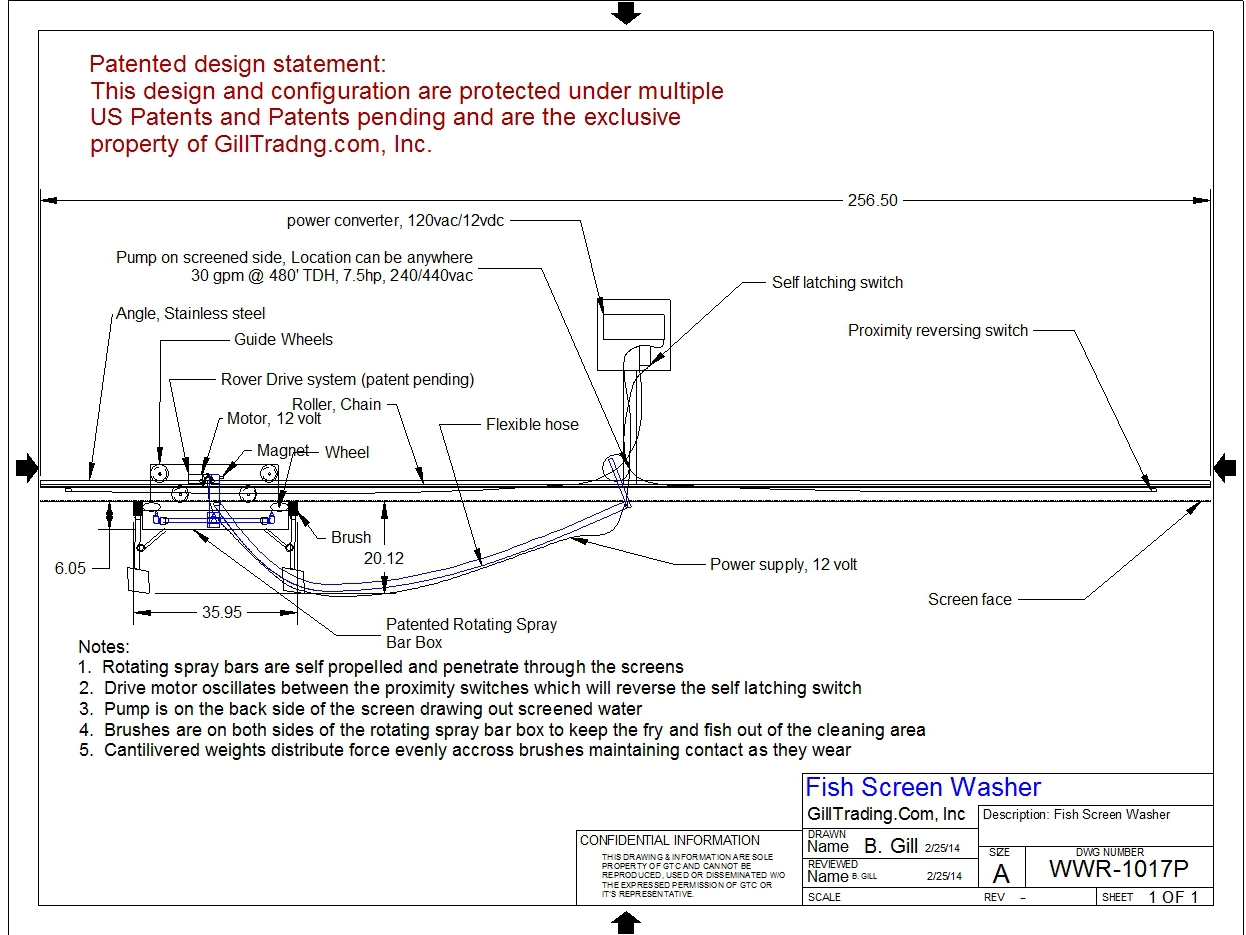

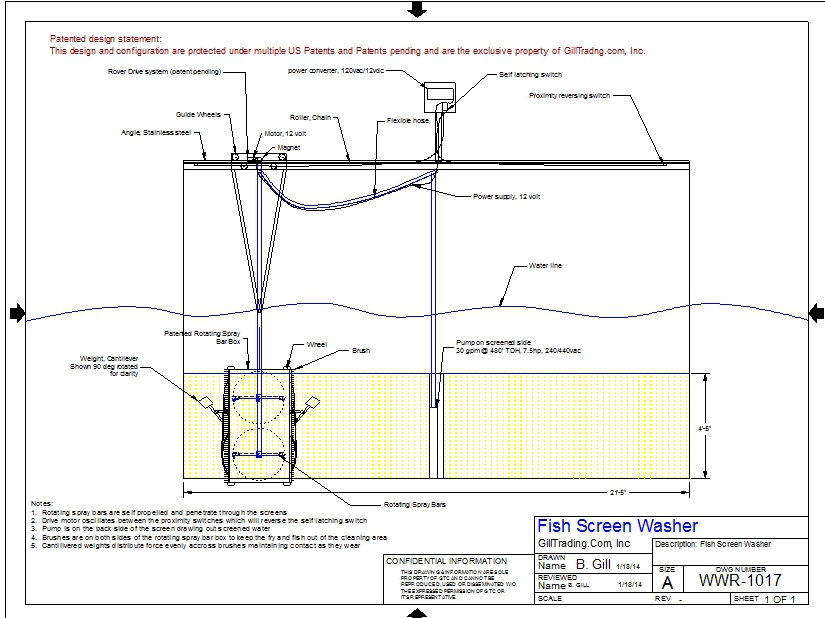

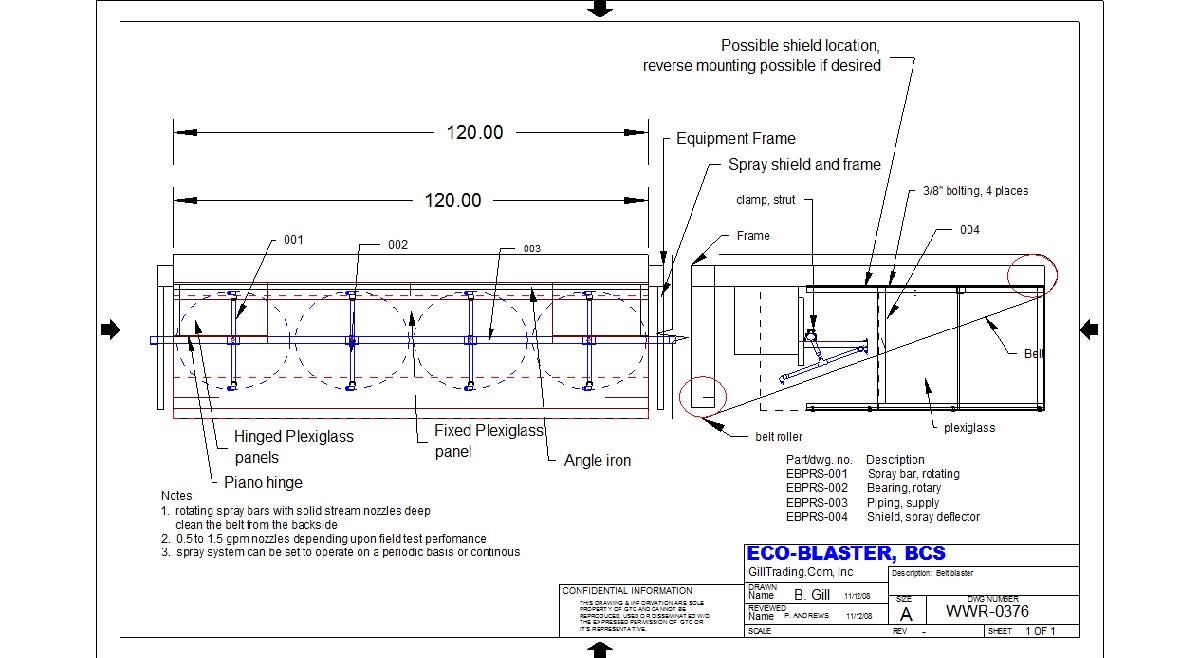

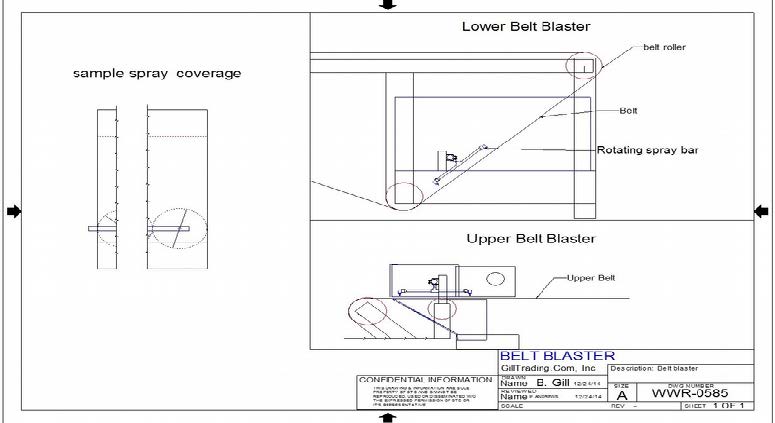

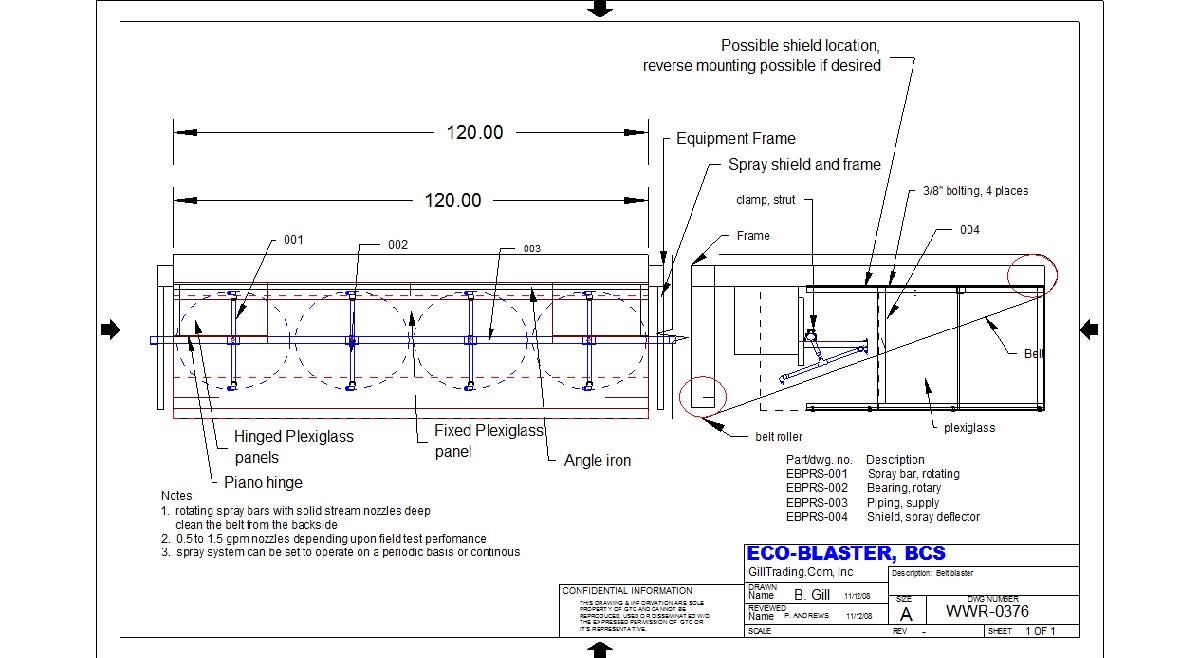

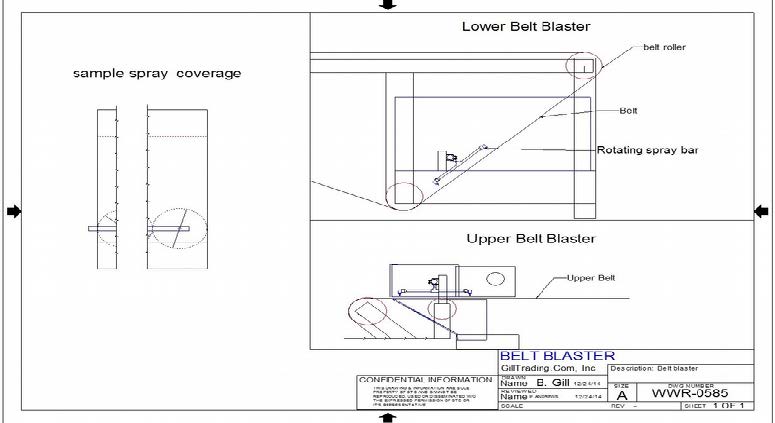

Now previously inaccessible applications can have systems for periodic automated cleaning. Engineered spray designs are applied to each application depending upon the material being controlled, varying from solid stream or flat fan, for heavier materials, to a fog spray for light material control. Materials being controlled include metal fines, polymers, algae, grease, wood pulp, fats, etc.

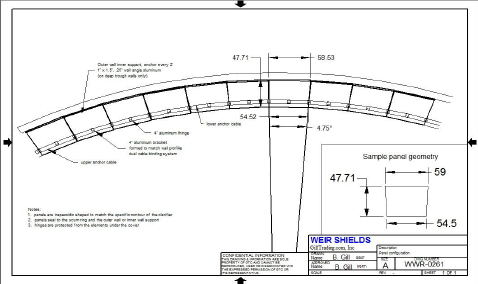

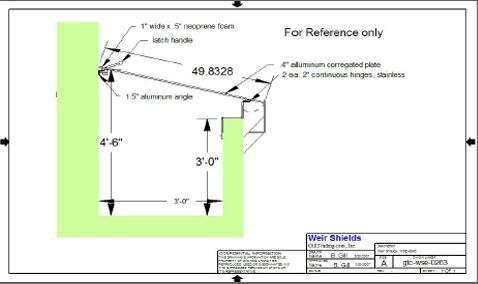

The diversity of the drive system and fluid delivery to any surface, either horizontal or to varying degrees such as post aeration step outfalls, allows for automated control and cleaning in all applications. Here are some examples:

Straight forward design enhances reliability and minimizes maintenance requirements. Some of the features of the Weir Rover, MCS are listed here: