Veteran-owned by a US Navy Submarines Nuclear Engineer.

Celebrating 31 years!

Cleaning clarifiers, thickeners, and the associated weirs, troughs and flow channels is necessary for the proper operation of tanks. If the weirs and scum baffle areas are left uncleaned, algae, grease and pin flock will build up in this flow area and reduce or stop flow in most of the clarifier. By reducing flow in most of the areas around the circumference of the clarifier, increased concentrated flow will occur, resulting in short circuiting flow. Short circuiting stops the settling action of the tank regardless of whether it is a thickener, decanter, or clarifier. This effectively bypasses the tank and it’s intended settling function completely.

During the summer months algae can grow up to 1″ a day. The growth and accumulation of undesirable materials such as algae, flock, paper stock, residual chemical precipitants, fats, oils and grease can build up and slough off creating blockage and problems in the UV chamber or the chlorine contact chamber, etc…

Many tanks are not easily cleaned and often require a person to enter the tank in order to dislodge debris. When this occurs, by law, OSHA guidelines must be followed to ensure worker safety and to protect your organization from any liability associated with the violation of federal laws regarding workplace safety. OSHA’s Permit-Required Confined Space guidelines have been established over many decades of applied lessons learned from employee deaths and accidents.

At Gillteq, our goal is for everyone to operate these inherently hazardous facilities safely, without any accidents or deaths. Our most valuable assets are the personnel who contribute to and maintain the operations of our facilities. Their continued health and safety are of the utmost importance as we understand their children and family are also depending on them. The primary purpose of Gillteq’s products is to automate the control of the growth and accumulation of undesirable materials so that your facility personnel is not exposed to or placed into these dangerous, and potentially deadly environments. If your facility staff is manually performing a regular house cleaning event, Gillteq can supply a combination of customized products to automate the process of routine maintenance and cleaning.

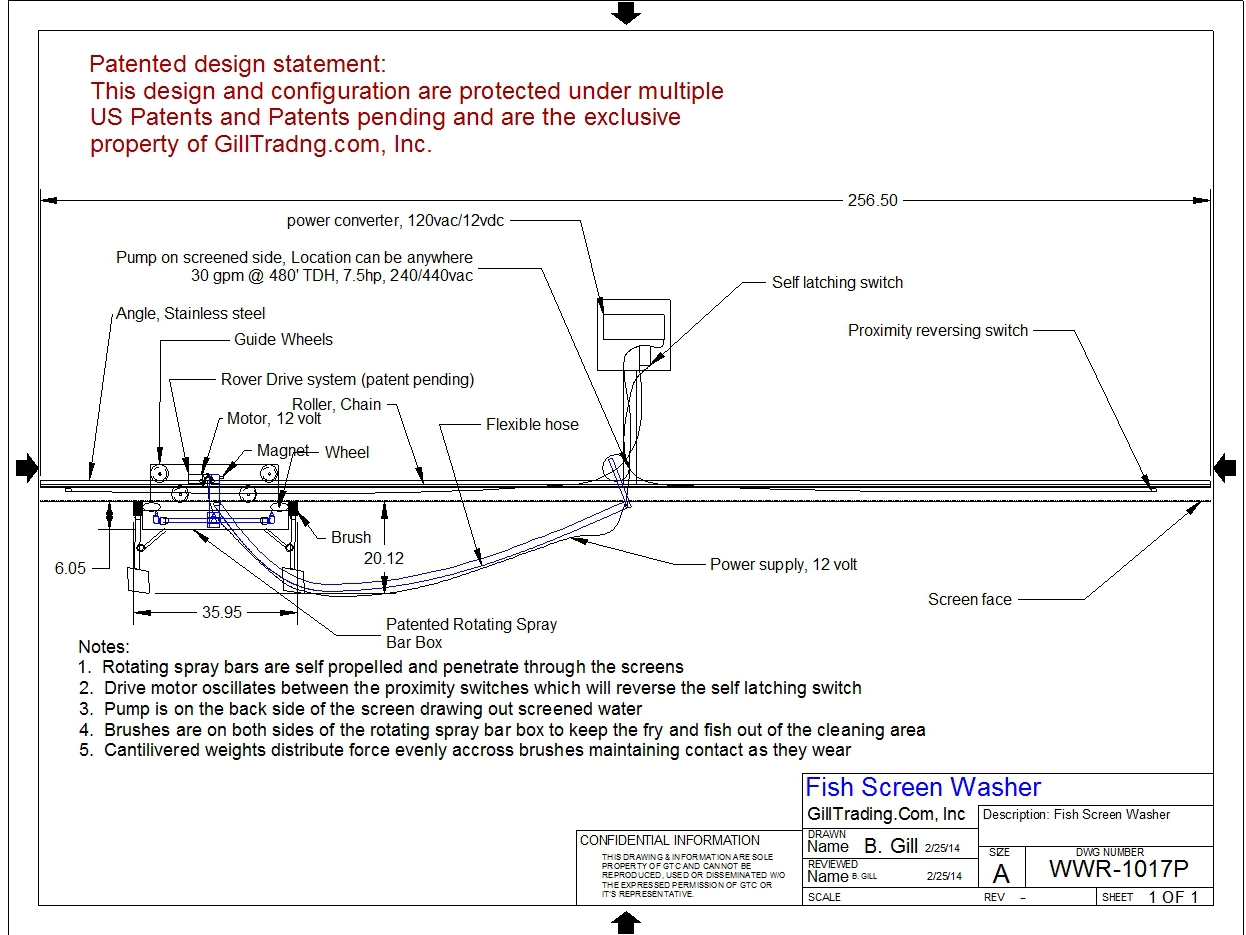

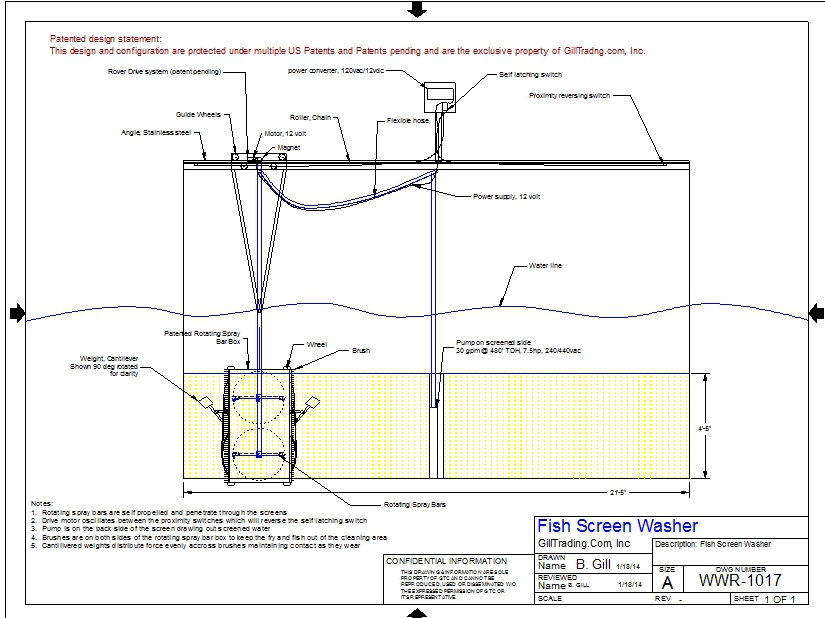

WeirWasher Automated Cleaning Systems (ACS) removes Algae, Grease, Debris, Scum, Foam, Sludge, and other materials from clarifier weirs and troughs.

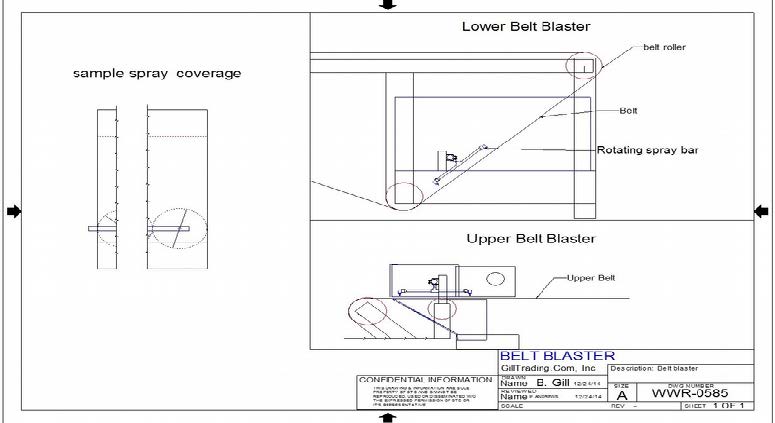

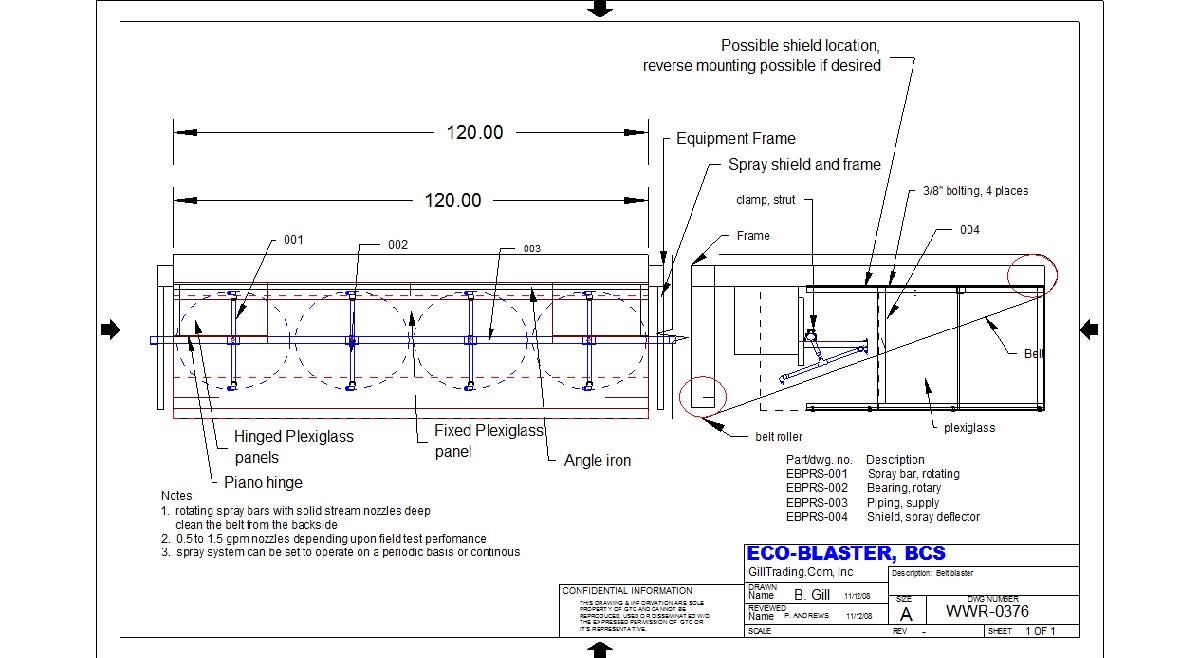

Eco-Blaster, Biological Control Systems (BCS) is used to control foam and material on tanks and clean screens and belt presses to name a few applications.

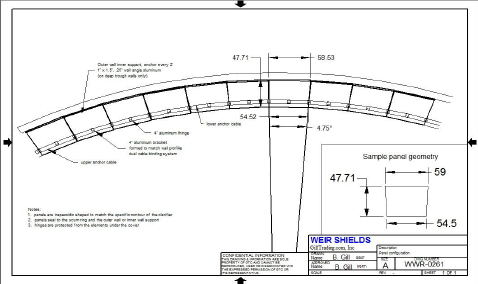

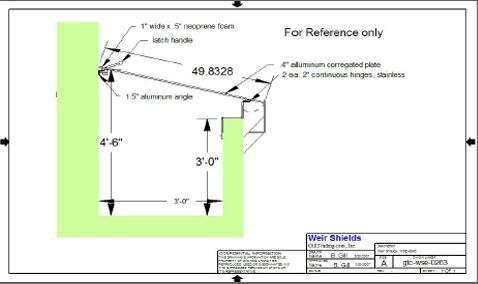

Baffled weirs serve to reduce, or eliminate surface turbulence and surges.