Veteran-owned by a US Navy Submarines Nuclear Engineer.

Celebrating 27 years!

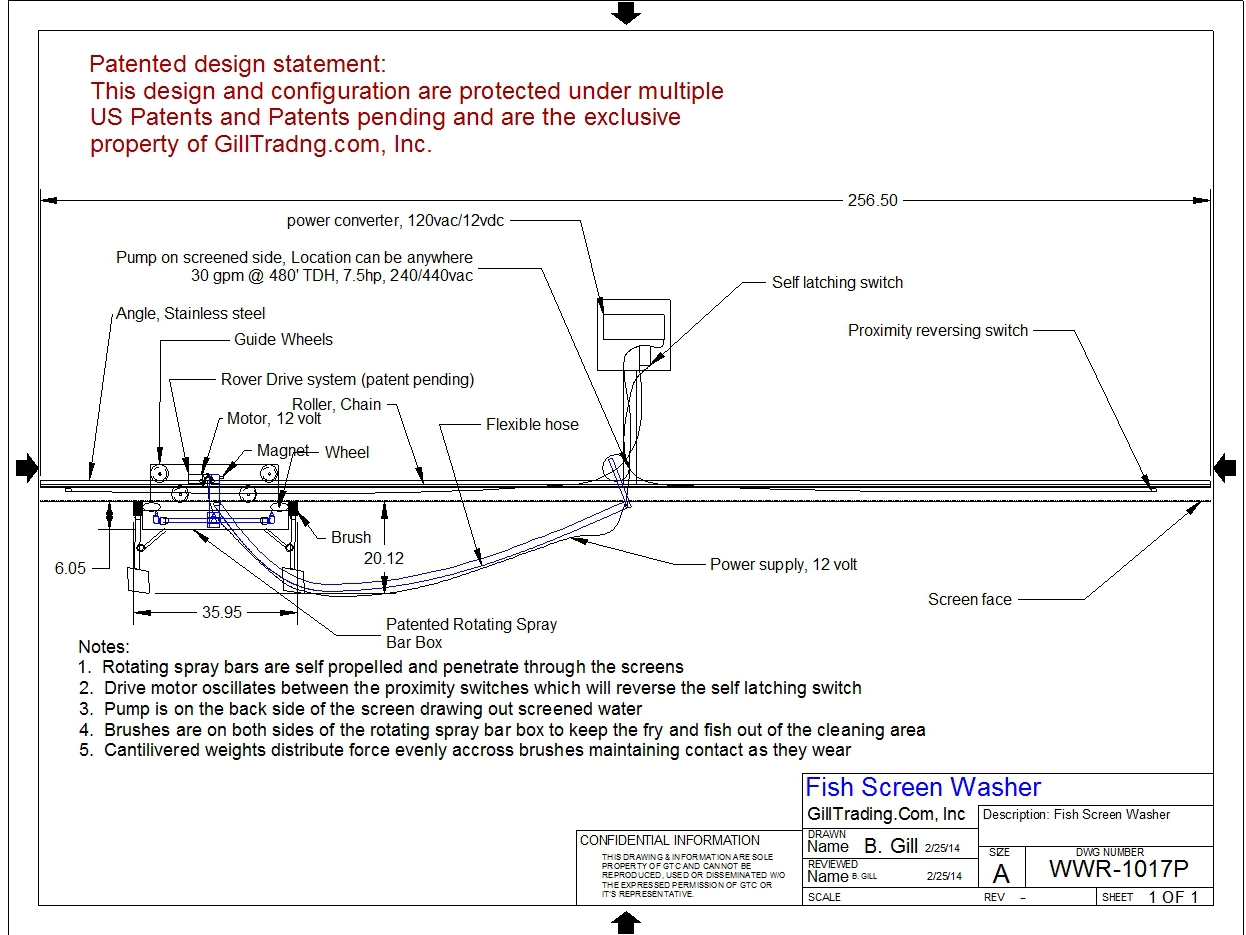

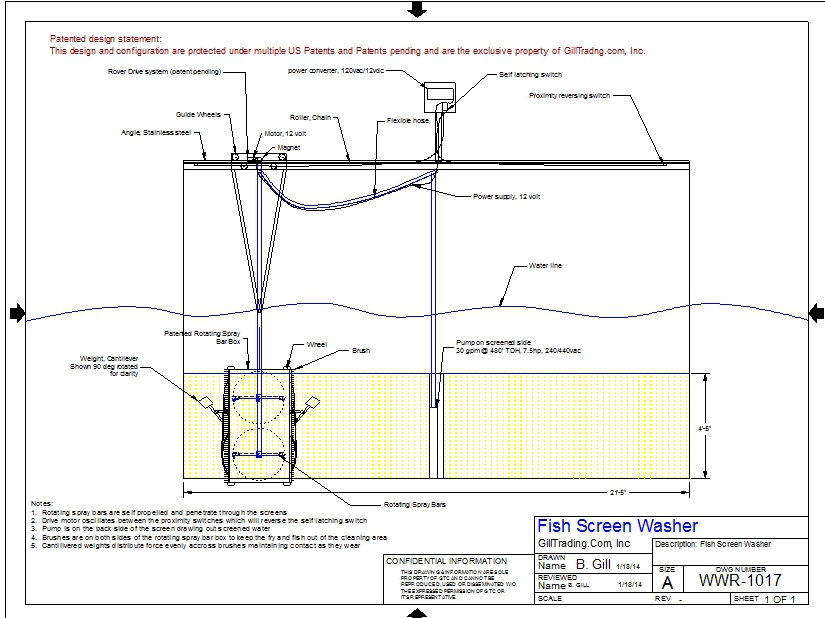

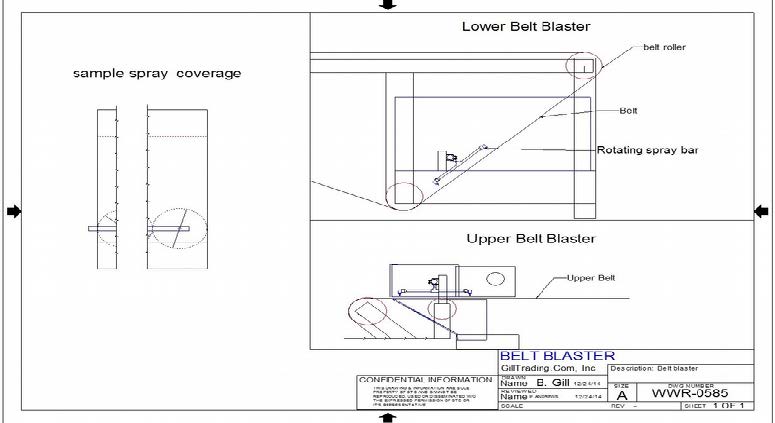

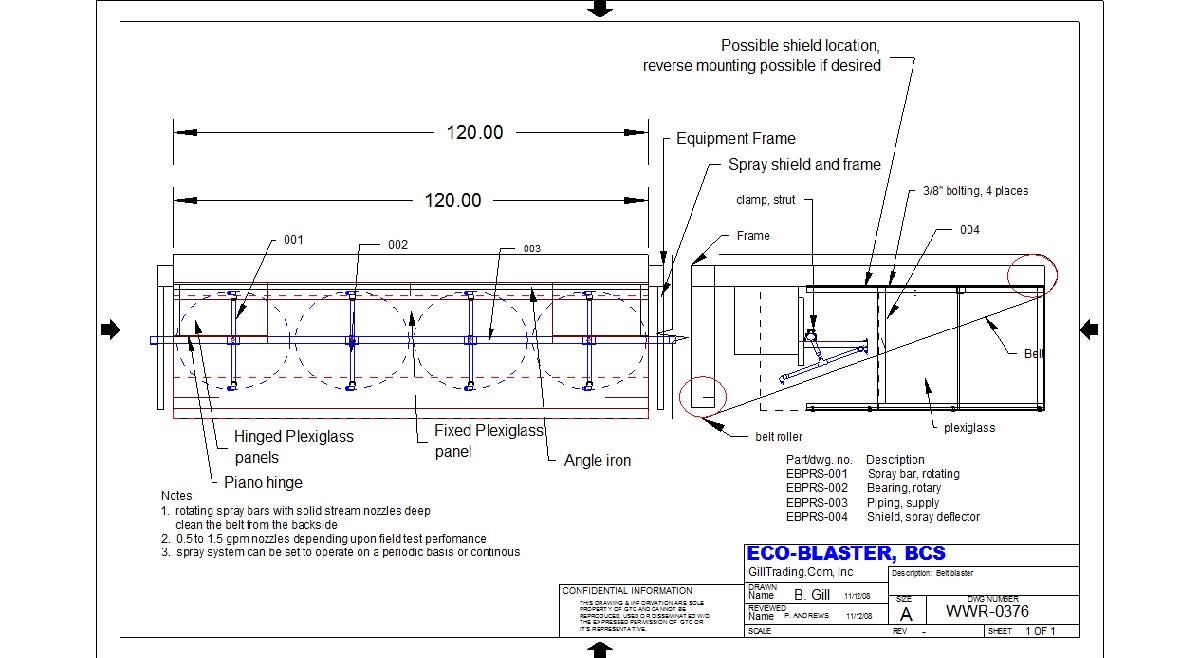

GillTeq manufactures safety related automated cleaning systems (WeirWasher, ACS – Eco-Blaster – Belt Blaster – Weir Rover) for paper mills, chemical manufacturing and water/wastewater treatment facilities. Our original designs were installed in 1994 and have been operating ever since. Through many years of research, development and testing, we have refined our products to their current state.

Over 50 trade secrets and multiple patents are associated with the manufacture and design of the GillTeq products. We have over 35 years of diverse spray, multi-nozzle, dual dynamic spray design applications. These include anything from 1000 psi/500 gpm hot rolled steel plate descaling to high-pressure/low volume roll and felt rotating-dynamic wash/cleaning for paper mills.

I perform the day to day management and operation of the business and directly control the R&D of new products as well as the improvement of the WeirWasher, ACS, Eco-Blaster, Belt Blaster and Rover product lines. In the past I have been involved in heavy industry primarily focused on the integration of operational practices relative to the MTBF/R of 500-20000 HP rotating equipment and their associated systems.

My past experience includes the following:

WeirWasher Automated Cleaning Systems (ACS) removes Algae, Grease, Debris, Scum, Foam, Sludge, and other materials from clarifier weirs and troughs.

Eco-Blaster, Biological Control Systems (BCS) is used to control foam and material on tanks and clean screens and belt presses to name a few applications.

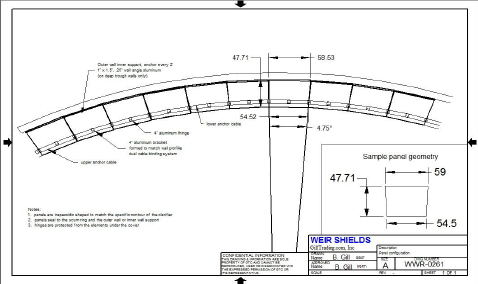

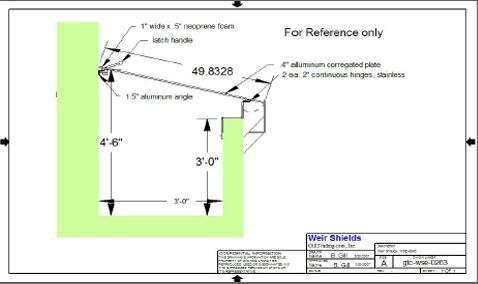

Baffled weirs serve to reduce, or eliminate surface turbulence and surges.